WHY WE NEED THIS SIMULATION

The 5S are the basis for stable and efficient processes.

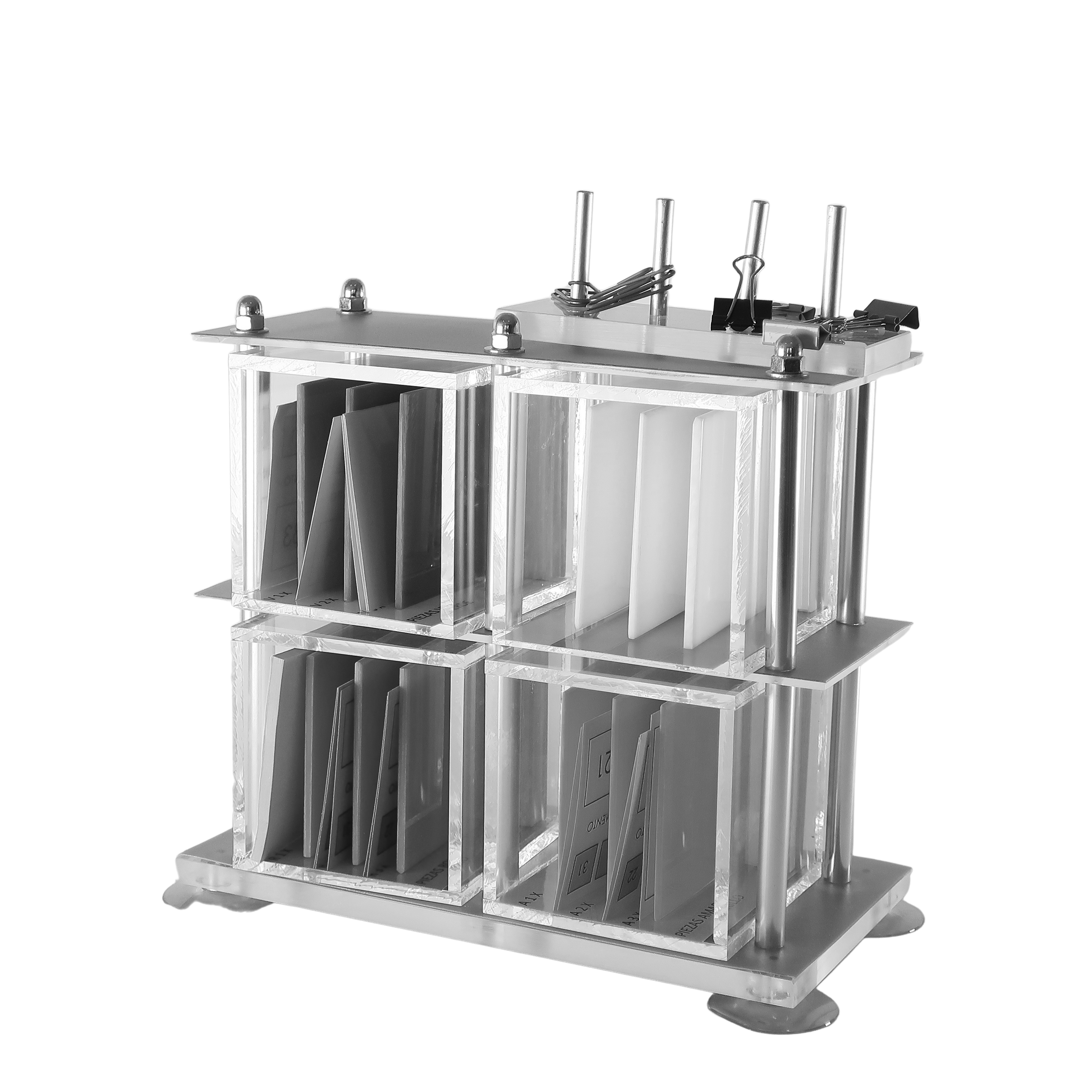

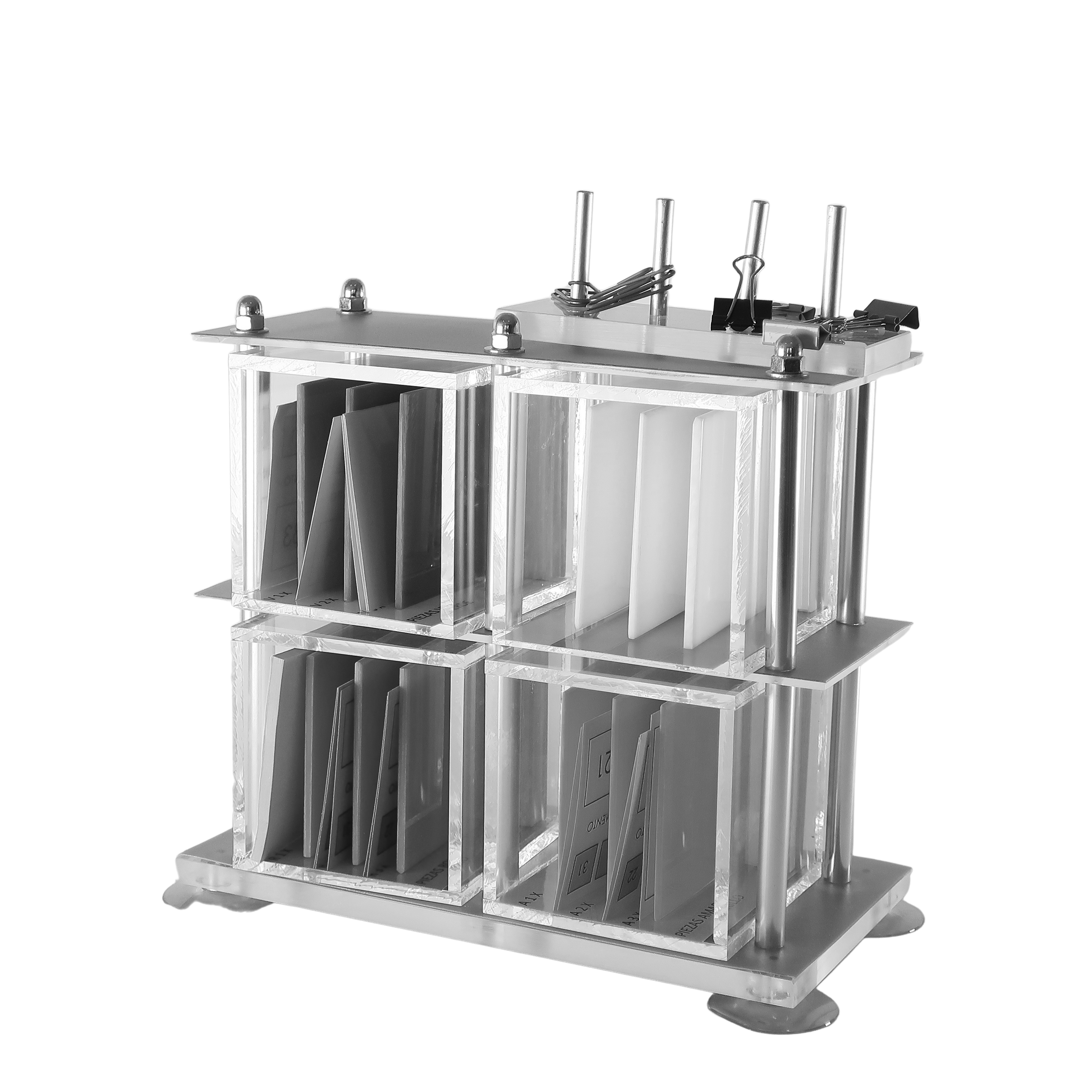

The 5S game is a simulation that combines both materials and information. In each of the game phases, a team of 2 people must complete a series of instructions. The simulation is carried out in 5 phases, through which the 5S are applied to the simulation itself.

PRICE: 650 EUR + VAT

WHAT ALLOWS US TO TRANSMIT

The first step of continuous improvement

The 5S are the elementary principles of Continuous Improvement, an important initial step that will help us to stabilise a process. In a next step this will allow us to apply other tools on a basis of order and cleanliness. This tool, like so many others, was developed and perfected in Japan and is one of the oldest and most common sense tools. Its main objective is to improve the working environment. The methodology consists of applying 5 concepts that coincide with the 5 Japanese words beginning with S and that define a series of consecutive stages:

In the first 'S' the main objective is to determine what is needed from all the items in the area. Everything that is unnecessary, infrequently used or in disproportionate quantities according to usual consumption will be removed from the work area.

The main objective of the second 'S' is to define a location for each element that, in the previous phase, we have decided will remain in the area. "A place for everything and everything in its place". Another important premise is that anyone can easily and quickly find and return items to their place.

The third 'S' has two basic objectives: on the one hand to achieve a zero point in the area with respect to the level of cleanliness, and secondly, no less important, to detect sources of dirt in order to eliminate them or, if this is not possible, to minimise them by containing the dirt and making it easier to clean by reducing the time spent on cleaning.

The fourth 'S' seeks to define ways of working, so that what has been achieved with the previous 3 'S' can be maintained over time, above all in terms of cleanliness, replacement of materials, auxiliary staff, etc. The standards are the support that allow the improvements achieved with the changes made to be maintained.

This last 'S', together with the standards of the 4th 'S', are the key to the sustainability of 5S over time. This last phase proposes systems to sustain improvement over time.

5S is the essence of basic process conditions

Methodology STEP BY STEP

The development of a phased training is revealing and instructive because it helps to generate knowledge in each of the phases, as participants identify the effects of every change introduced with respect to the previous phase. The Apex Mindset games are structured as follows:

1 Introduction

Definition at the beginning of each phase of the challenge and the scope of the problem faced by the team

2 Training

Explanation of the theoretical contents to be applied to solve the problem posed by the game

3 Application

Development of the game phase, applying the concepts explained in the training

4 Learning

Review of the results and assessment of the contribution of each of the concepts introduced. Moving on to the next phase

1. Introduction

2. Training

3. Application

4. Learning

PRICE: 650 EUR + VAT

The game helps to experiment in a safe environment

The trainer should be an expert in facilitating games and simulations with experience in leading improvement teams.

Game to be played in a large room so that players and observers can share and participate in the experience.

The game is designed to take between 1 and 2 hours, depending on the content of the training.

All in one box: what you need for the facilitation and development of the game is all included inside the product box.